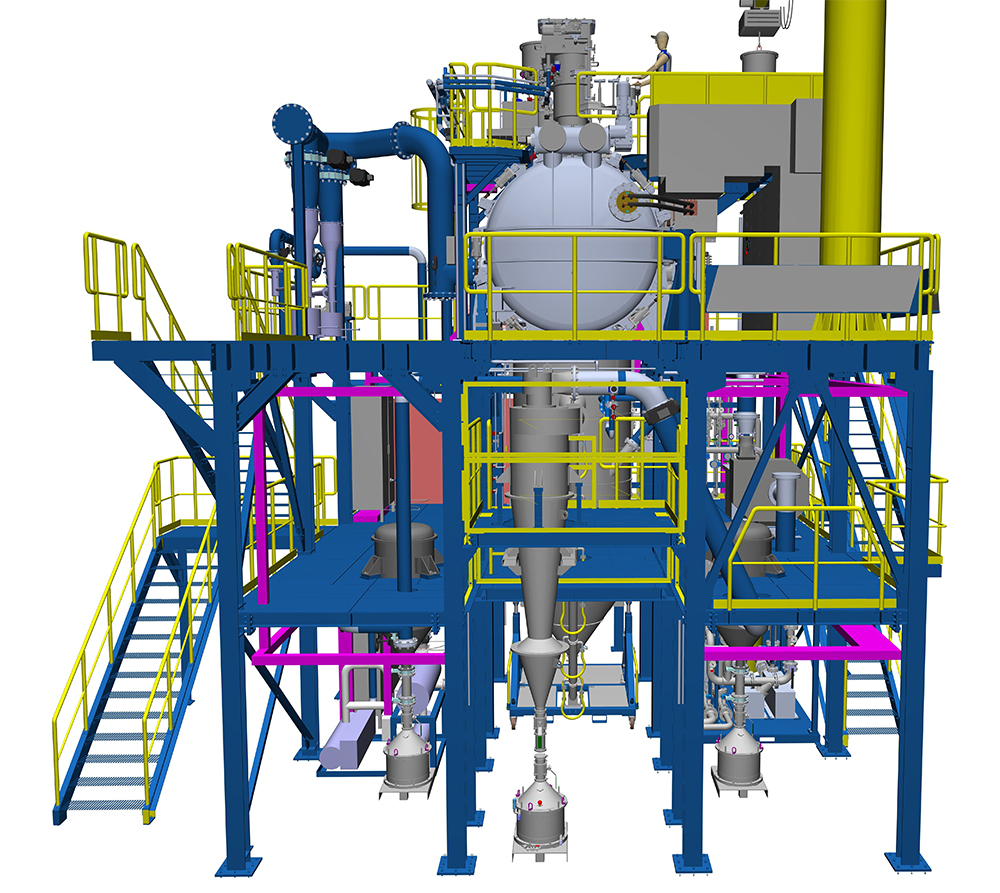

- Design based on decades of experience on VIM plants and atomizing process and equipment

- Able to operate at higher temperatures than standard gas atomizers, suitable for high-melting point and refractory alloys

- High-vacuum pumps for minimum content of oxygen and residuals

- Special nozzles dedicated to specific alloys and particle sizes

- Developed for maximum FLEXIBILITY

Technology

Atomizing Equipment

Post processing

All machines have internal stainless steel mirror polished surfaces and work under inert gas, preventing any risk of contamination. The isolation of each process from the others and the strict clean-down regimes ensure that we maintain the integrity of every customers’ material, every time.

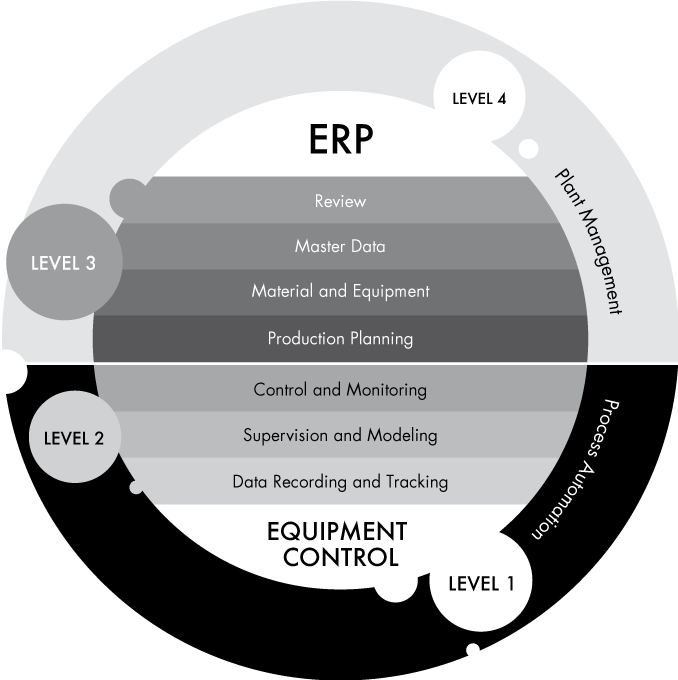

In accordance with Industry 4.0 all machines are controlled by PLC panels for powder process route integration and maximum control for traceability.

All the equipment used for powder production and characterization have the technical and scientific characteristics to be included in the European plan named “Industry 4.0”. In fact their functioning is controlled by computer systems and the most complex equipment are able to control the working conditions and the process parameters through proper sensors, applying an adaptive behaviour to the process deviations. Moreover all processing machines and laboratory instruments include a simple and intuitive human-machine interface in accordance with ISO law and meet the latest safety, health and hygiene at work standards.